Production of Fish Feed from Local Feedstuffs

By 1993 it was becoming clearer that fishing from the wild cannot sustain fishery needs in Nigeria. Inland aquaculture in Nigeria produced 15, 576 metric tons with per capita availability of 5 kg of fish compared with per capita fish supply of 25.4 kg and 7.7k g for developed and developing countries, respectively (Coche et al., 1994). Hence, Nigeria had become a net importer of fish. With the Structural Adjustment Programme (SAP) and the devaluation of the Naira, fish importation declined. By 2001 the aquaculture production in Nigeria was only 24,395 metric tons (FAO, 2003). There was thus increasing pressure on aquacultural products. Aquaculture production depends on a major production of adequate artificial feed for fish. Feed represents the single most expensive production cost in aquaculture operations (Shang, 1981) comprising over 50% of the running costs. It, therefore, needs adequate attention if aquaculture has to succeed.

In terms of nutrition, fish can be broadly grouped into, carnivores for fish that feed on other animals, herbivores for those that feed on algae and other plants, and omnivorous those that feed on plant and animal materials. The feeding habit of fish is usually considered when producing feed for the species. Again, larval fish are fed differently compared to other fish. Feed production is to as far as possible, take care of the gastronomic habits of the target fish. This is done by preparing feeds that meet the specific nutritional and physical property needs of the fish. The production has to recognize the slow feeder, the fast feeder, the surface feeder, the mid-water feeder, and the bottom feeder.

Below are terms used in the nutrition of most cultured fish:

Fish feed is that material given singly or in combination to fish which may not be necessarily what it consumes in nature. Fish food, on the other hand, is the edible material that fish choose to consume in their natural environment to furnish nutrients to the animal. At times, however, the term fish food is used to include both prepared diets and natural nutrients. We will stick with the first definition. A diet is any substance prepared as a nutritional substitute for fish food. A nutrient is a dietary constituent of feed or food that aids in the growth and support of life processes. The ration is a 24-hour diet allowance for the animal. A material or mixture of materials to make an allowance for 24 hours.

Some principles to be considered in aquaculture include:

(A) Fish is poikilothermic i.e. cold-blooded animals and its energy of metabolism differs from those of homoeothermic (warm-blooded) animals. Fish do not need as much energy for metabolism. Commercial diets used for some important species of fish such as channel catfish for grow-out purposes as a result usually contain 32% crude protein and 3.0 kcal digestible energy (DE)/g of diet, for digestible energy: protein ratio (DE/P) of 9.4 kcal/g of protein (Reis et al., 1989).

(B) Carbohydrate is more poorly digested in most fish than in land animals. A lot of carbohydrate feed is excreted. Recent research, however, has shown that Clarias spp. efficiently utilize non-protein energy from carbohydrates and can improve protein retention (Luquet and Moreau, 1990).

(C) In protein metabolism nitrogen is excreted by most fish as free NH3 in water. About 80% of excess nitrogen is excreted as NH3. In terrestrial animals, excess nitrogen is excreted in urine and this process requires energy. The nitrogen is excreted as urea and hence a loss to the animal in the form of carbon, oxygen, and hydrogen which are excreted with every molecule of nitrogen. Fish is therefore more efficient in the excretion of nitrogen needing less energy and wasting fewer materials.

(D) There is no danger of overfeeding land animals. Overfeeding fish affects the water quality. Floating feed is an advantage in pond feeding, though slightly more expensive than sinking pellets because the fish can be seen feeding and how much feed to offer to the fish without wastes can therefore easily be determined (Mgbenka and Lovell, 1984).

(E) Fish absorbs dissolved nutrients such as Ca++, out of the water. Inorganic phosphates (PO42-) are not much found in water. Phosphorus is bound up in the bottom mud hence the need to fertilize ponds especially when the Secchi disc visibility exceeds ≥ 45 cm. Most organic and inorganic materials are picked up across the gills into the bloodstream. Nutrients that are not picked up or manufactured by fish at all or in sufficient quantities in culture conditions are supplemented in the feed e.g. vitamins and minerals.

(F) For a high per cent crude protein diet we require a high percentage of protein supplement feedstuff in the finished diet and vice versa for a low per cent crude protein diet.

Feedstuffs or Feed Ingredients

Feed ingredients are chosen to satisfy the protein and energy requirements of the target species for which feed is made; essential minerals and vitamins are always added as supplements. As a result of this feedstuffs are broadly classified as protein or basal feedstuffs. For the production of feed on farms the choice of ingredients should be such that they provide protein, carbohydrate, and fat at less expense without sacrificing the amino acid requirements of the target species.

The major local feedstuffs that meet the protein needs of most species without sacrificing amino acid requirements are corn, soybean meal, and fishmeal. Using these ingredients in combination in fish diets ensures that what amino acid that is lacking in one feedstuff is augmented by a relative excess in the other e.g. low methionine in corn is synergistically replaced by that in soybean (Lovell, 1989).

These feed ingredients are, however, expensive for their use in fish competitions which humans and livestock feed. Trash feed can be used as is practised in Asia (Jantrarotai and Jantrarotai, 1993) for making catfish and carnivorous fish feeds but the use is limited to farmers living on the coast and there may be the use of treatments such as pasteurization to kill potential human pathogens such as Salmonella spp. The high expense of these conventional feed ingredients demands that other unconventional ingredients be used for fish feeds. Even fishmeal has become so expensive that substitute ingredients for fishmeal have been sought (Viola et al., 1982). Charred fish fines of less human nutritional appeal are shown to be good as a fish feed ingredient for cash-strapped and cannot go for better feed ingredients (Mgbenka and Agua, 1990). Presently, several unexplored unconventional feedstuffs would not compete stiffly with human or livestock diets.

Oyenuga (1968) did extensive work and reported the nutrient contents of many Nigerian feedstuffs. These include those used for human and livestock nutrition and some unconventional feedstuffs such as peels, some roots/tubers e.g. cassava, cocoyam, sweet potato root, yam; some leaves e.g. sweet potatoes, cassava, sugar cane, Telfairia; some concentrates e.g. Acha grains (Digitaria exilis Stapf.), Bambara groundnut, cocoa beans, cotton seed, groundnut cake, guinea corn grain, millet (bulrush’s grain), Mucuna seed (Mulcuna spp. Adams), Palm kernel cake, rice bran, whole soya bean, sunflower seed, yellow maize; dried leaves hay and husk e.g. cowpea husk, cocoa husk, green gram husk, rice husk, ground nut husk; and even miscellaneous ingredients of which some are relatively high in crude protein (CP) e.g. plantain peels ripe (CP, 9.14%), plantain peels unripe (CP, 10.64), pawpaw leaves (CP, 32.6%), mango green fruit (CP, 35.0%) blood meal pure dried (CP, 88.46), blood meal mixture (CP, 33.72). Only estimated digestible nutrient values were given for the feedstuffs reported by Oyenuga (1968).

Other unconventional ingredients have been used for Clarias gariepinus e.g. toad meal (Annune, 1990). Elsewhere, other conventional materials like earthworms which abound in Nigeria but which have been reported to be low in essential amino acids for temperature fish have been recommended to be used only at low replacement levels for fish meal (Amerio, 1983; Tacon et al., 1983). Other suggestions such as the use of sprout, a by-product of sorghum malting (Okwuosa, 1994), and rumen digesta which is abundant as abattoir waste as fish feed ingredients are plausible but not much-published work has yet been done with these in fish nutrition. It is envisaged that rumen digesta which contains a lot of fibre may be problematic in terms of digestion. Many other feedstuffs from which choice of ingredients can be made when formulating fish feeds (if locally available) are found in many standard nutrition books (e.g. N. R. C., 1993; Ensminger and Olentine, 1978) and need not be detailed here.

To produce efficient fish feeds there is a need to determine the digestible nutrient values of local ingredients for fish. Only very little work is done on the digestibility of feedstuffs for Nigerian fish species (Mgbenka and Agua, 1990). Again, some plant proteins e.g. soybean meal and most other legumes have been reported to have anti-nutritional factors such as protease inhibitors and lectins (Liener, 1980) and some may need heat treatments to denature the factors. Also, some plant ingredients are deficient in certain essential amino acids such as methionine, tryptophan, and lysine which are required for good fish growth (Moses, 1983), while yet others e.g. sorghum, most grains have phytic acid which ties up phosphorus in the form of phytate phosphorus which is poorly available to fish, reduces the bioavailability of zinc and other elements and depresses protein digestibility thereby resulting in poor growth (Christensen, 1981; Lovell, 1989).

Feedstuffs such as coffee pulp and sorghum have tannins that lead to poor growth in fish when supplemented at high levels. This dictates the need for additional supplementation of feed with phosphorus in such forms as dicalcium phosphate in an all-plant fish diet (Lovell, 1989, Mgbenka and Ugwu, 2005; Ugwu et al., 2005). Other toxins which preclude the use of unconventional feedstuffs in fish feeds include gossypol, cyclopropionic acid (Lovell, 1989) enzyme inhibitors, and aflatoxins (De Silva and Anderson, 1995). Gossypol in cottonseed meal is moderately toxic to non-ruminants such that only 7.5% – 15% solvent-processed cottonseed meal is recommended in fish diets.

Treatment of 0.85 to 1.0 part ferrous sulphate to 1.0 part free gossypol has been reported to block the toxic effects of gossypol in monogastric swine (Tanksley, 1970) and possibly in fish. All varieties of cottonseed meals have cyclopropenoic fatty acids which cause a lot of complications in fish rendering the use of cottonseed meals risky. Animal protein sources e.g. poultry and farm animal offal are more scarce but where available as in the case of some integrated farms, they can be used for on-farm fish feed production. Some care and proper treatment have to, however, be exercised when feedstuff is selected for making fish feeds to ensure that wholesome ingredients without disease agents are selected.

Also See: 7 Things to Consider Before Starting a Fish Farm

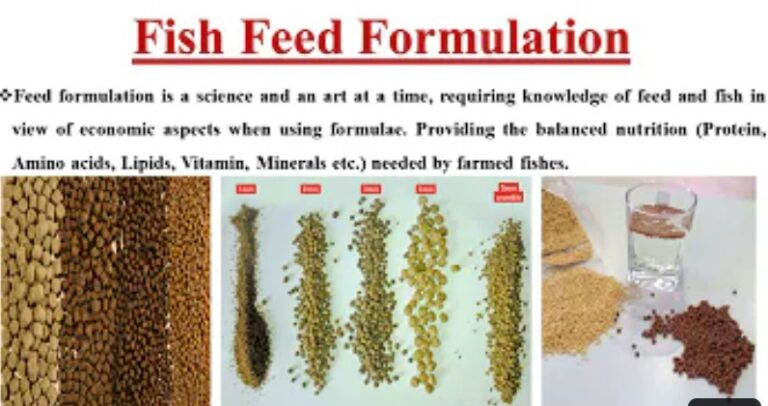

Feed Formulation

Nutrition performance and success of artificial diet for aquaculture depend to a great extent on feed formulation and manufacturer, on-farm feed management, and aquatic environment.

The series of technical and economic considerations in the formulation of feed are:

The market value of the species to be fed: The table size price of the species should be considered so that in general the dry diet cost should not be more than 25% of the market table size value of the cultured species.

The financial resources of the farmer (if homemade fish feeds are to be produced): The capital available for the purchase of feed ingredients and Feed manufacture and equipment and availability of services Such as electricity and fuel should be considered.

5 Major Factors determining the nutritional performance and success of an artificial diet feeding regime (After Tacon, 1993)

- Feed formulation and Nutrient content

- Feed manufacture and physical characteristics

- The aquatic environment and Natural food availability

- Feed handling and Storage

- Feed application method & feeding regime

Dietary nutrient requirement of the species to be fed (or closest relative)To include dietary protein, amino acids, fatty acids, minerals, Vitamins, and requirements for such phase of the culture cycle (namely, for larvae/fry, juvenile and brood stock productions (if known).

Natural feeding habits of the species in question (if known) When such information is not available some insight into the dietary nutrient requirements can be gained from analysis of its natural feeding habits in the wild to indicate the position in the aquatic food chain (i.e. herbivore, detritivore, omnivore or carnivore), preferred food items and food size (i.e. plant and animal feedstuffs), feeding station (i.e. surface, mid-water or benthic feeder), and feeding behaviours (i.e. daylight or nocturnal feeder, visual or olfactory feeder, rapid or slow feeder, continuous or intermittent feeder). An analysis of the natural target species gives an insight into the physical characteristics of the artificial diet to be produced (i.e. feed size and shape. Texture, palatability, buoyancy, and water stability).

Available feed ingredients, sources, composition, and cost Seasonal availability, current usage of the ingredients, proximal composition, quality control, digestibility, nutrient availability, additional ingredient handling, and processing cost before mixing or pelleting need to be considered before the use of a particular feed ingredient.

Intended feed manufacturing process to be used. Grinding, mixing cold pelleting, steam pelleting, hand molding, expansion pelleting, flaking, and/or microencapsulation. The formulation will depend on whether the diet is to be produced as mash (meal), crumble, paste, ball, moist pellets, or dry pellets.

Intended stocking density and farm production unit. Extensive, semi-intensive, intensive systems with tanks, raceways, concrete-lined ponds, earthen ponds, pens, or floating cages. The stocking density will determine the relative natural feed organisms per unit biomass of cultured animals (fish/shrimp). As a general rule, the contribution of natural pond organisms to the nutritional budget of cultured aquatic species will be highest at low stocking densities or the start of the culture cycle. At the start, the total biomass (standing crop) is the lowest. The contribution of natural food decreases over time during the production cycle with the increasing size of cultured organisms and standing crops. This is true, especially for non-carnivorous fish species. In semi-intensive fertilized pond systems with mostly non-carnivore fish species, as the difference between the standing crop of natural food organisms increases, the deficit in the natural protein supply also increases. Supplementation with a protein-rich diet becomes necessary for the latter condition to maintain growth in the system. Hepher et al. (1971) and Hepher (1975) reported that the growth of common carp was not affected by a 9% crude protein pelleted sorghum diet until a standing crop of 800 kg/ha because natural food was enough at a lower stocking density. It became effective in improving growth at 800 kg/ha only to become ineffective later when a 22.5% protein diet became effective up to a standing crop of 1400 kg/ha and thereafter dwindled in effectiveness. In intensive clear-water systems where natural pond organisms play little or no role in the nutrition of the organisms, the reverse is the case i.e. dietary nutrient levels usually decrease with increasing fish size and age.

Dietary energy is usually the first limiting factor (nutrient) within earthen ponds at low fish stocking density. As the stocking density and standing crop increase, the requirement for supplemental dietary nutrients such as protein, minerals, and vitamins also increases. The dietary protein and essential micronutrients of supplementary feeds intended for semi-intensive aquaculture pond systems should be low at the start and progressively increased. In semi-intensive systems abundant natural pond food organisms sufficed for the needs of the cultured species at the beginning because many of them are rich in protein hence the reduced level of inputs recommended at the start.

Some other points to note or things to seek out when formulating fish feed:

- Nutrient requirements of the species if known in available – amino acids, lipids, vitamins. If not known those of related species can be used.

- Protein (crude) requirements of the species. This varies from 30 – 55% for many fish species. Invariably fish feeds are balanced from the protein content of the finished diet rather than for the energy in the finished diet. This is so because protein is usually the more expensive input in the feed.

- Based on the type of fish chosen the crude protein range to work with e.g. for larval freshwater fish, 40% may be chosen for catfish; herbivorous and omnivorous species usually require lower crude protein levels e.g. 32% – 35% crude protein compared to ≥ 40% – 45% crude protein input for carnivorous fish like snake fish (Chana obscura) and shrimp.

- It is important to know the percentage of nutrient levels in the available feedstuffs. Nutrient requirements tables from the National Research Council (NRC),

- Formulation of the diet should be started using any of the available methods e.g. trial and error method or Pearson’s square method.

- For a high per cent crude protein diet, we require a high percentage protein supplement feedstuff in the finished diet, and vice versa for a low per cent crude protein diet.

- Through digestibility and resultant availability of nutrients for any feedstuffs to fish may be affected by such factors as temperature, meal size, and possibly body size, it is assumed that any nutrient in any particular feedstuff is just as available as the same nutrient in another feedstuff i.e. low cost determines which feedstuff to use. It is possible to make an infinite number of feed formulations to meet the nutritional requirements of fish. Some of the simple methods used include:

- Pearson’s method,

- Trial and error method,

- Solving simultaneous equations

Pearson’s method (De Silva, and Anderson, 1995)

In this method, the formulation can be done by balancing crude protein level, energy level, or cost. Usually, protein is used.

A. Balancing crude protein level.

Protein is usually expensive and is the first nutrient to be computed for. The energy level is adjusted to the desired level with high-energy supplements at lower costs. Fish feed to meet the energy requirements.

For diet formulation using soybean meal (SBM) and rice bran (RB) the square method (Pearson’s) can be used thus:

- Draw a square and diagonals of the square.

- Place SBM and RB at the left corners of the square with their respective crude protein contents.

- Write down the desired crude protein content of the diet at the intersection (middle) of the diagonals of the square.

- Subtract the protein level of the feed from those of the feedstuff and write answers at the right opposite diagonal corners from the feedstuff. Ignore negative and positive signs. Total up the values at the right-hand corners.

- The proportion of the feedstuffs to mix is:

RB = 14000/358% = 39.1% of rice bran

SBM = 21800/358% = 60.9% of SBM.

- For more than two feedstuffs available for formulation these are grouped in such a way that those with crude protein (CP) < 20% are regarded as basal feedstuffs while those with CP > 20% are regarded as protein supplements. Average values of CP are found and as in the SBM – RB above to calculate joint quantities of feedstuffs required. For example, to produce a 27% tilapia or common carp diet or African bony tongue (Heterotis niloticus) diet using rice bran, yellow corn (c), and SBM and shrimp meal (or fish waste) as was reported by Pillay (1980).

Basal feeds required = 21.35/39.15 = 54.53%

corn and rice bran. Protein supplement required = 17.8/39.15 = 45.47%

To make 100 kg of feed, the different feed ingredients required will be:

- Rice bran = 54.53/2 = 27.265kg

- Corn = 27.265 kg

- Soybean = 45.47/2 = 22.735kg

- Shrimp meal = 22.735kg.

Some feed ingredients e.g. fishmeal to be used in the diet may be fixed. For a 26% crude protein diet suggested by New (1987) where fishmeal from previous experience was pegged at 10%, using groundnut cake with 34.5% crude protein and rice bran with 13.3% protein, the computation of the number of ingredients to be used can be done thus:

The actual amount of each ingredient should be:

Basal feed = 21.35/39.15 = 54.53%

Protein supplement = 17.8/39.15 = 45.47%

With rice bran and corn as basal feedstuffs and soybean mean and shrimp meal as supplemental feedstuffs:

Thus, to make 100 kg of this feed one would mix the following:

- Rice bran 27.265 kg

- Corn 27.265 kg

- Soybean 22.735kg

- Shrimp meal 22.735 kg

Usually it is advisable to start with about three feedstuffs:

- One high in protein and high in ME

- One low or intermediate in protein and high in ME

- One low or intermediate in both protein and energy. It is necessary to make allowance or fix the level for feed additives (vitamins, mineral premix, antioxidants (e.g. butyl hydroxyl toluene (BHT), Ethoxyquin, drugs, etc).

Later, levels of essential or indispensable amino acids (AA) are checked to ensure that the levels meet the target species’ requirement for amino acids. If the levels of arginine, lysine, methionine, and tryptophan are met, it is most likely that the dietary requirements of the other six amino acids will be met. If unconventional protein supplements are used to eke out low levels of amino acids in the feedstuff, the level of all the amino acids should be checked. The ten essential amino acids include; Phenyl Alanine, Valine, Threonine, Tryptophan, Isoleucine, Methionine, Histidine, Arginine, Leucine, and Lysine. Feedstuffs that are rich in the deficient AA are added at the expense of other ingredients. After this, the levels of protein and energy are rechecked to ensure that they still meet the requirements for the species.

Advantages of this method:

- It is easy i.e. simple to apply.

- It can be used to calculate the proportions of feedstuff to meet protein and energy levels.

Disadvantages of this method:

It cannot be used simultaneously to solve for both protein and metabolizable energy (ME) levels.

Other methods

i. Best buy technique

For energy, the best buy technique is also employed when considering which feedstuff to use. For example, if brewer’s waste costs N0.0858/kg; and contains 1,2000 kcals ME/kg, i.e. cost/kcal = 0.0875/1,200 = N0.0000715/kcal and wheat middling waste costs N0.1883/kg while containing 1,663 kcal ME/kg i.e. wheat middling costs N0.00001132/kcal. Hence, though brewer’s waste is lower in ME, it is less expensive to use in terms of cost/kcal.

Similarly, for protein, if anchovy fishmeal is at a cost of =N=0.5357/kg, and 70.9% CP and herring fishmeal at =N=0.4709/kg, 76.7% protein, cost per kg protein = 0.470/0.767 = =N=0.161395/kg. Hence, herring meal is better for use i.e. less expensive of the two.

ii. Cost per unit of amino acid

Cost per unit of amino acid can also be employed to compare feedstuffs. When using such comparisons, the availability of the nutrients to the animal should be kept in view, where the nutrient is not readily available to the fish in both feedstuffs, the comparison is not valid.

Feed Processing

- Feed processing operation can be summarized as comprised of

- raw material size,

- feed forming and

- feed drying (Wood, 1995)

To effect these, equipment of some form ranging from crude to sophisticated is needed. Some options in fish feed processing are given in Table 1 below:

Table 1: Options for Feed Processing Equipment

| Process operation | Equipment | Raw material/product |

| Size reduction | Mortar and pestle

Mincer

Hammer mill Plate mill |

Dry of moist grinding or blending

Wet materials e.g. Trash fish/offals coarse – fine dry materials coarse – fine dry materials |

| Blending | Physical

Mechanical mixer

Horizontal Vertical |

Use for small quantities

Items such as variable efficiency As shovel, spatula, etc

Feet Bowl moist day

Dry powders or moist crumbs Dry powders. |

| Forming

Drying |

Hand

Mincer Pelletier Cooker extruder

Solar Mechanical |

Dough ball

Moist noodles Dry pellets Semi-moist/dry pellets or noodles

Variable efficiency Controlled drying |

Larval feeds

For year-round intensive production of fry, there is a need to develop artificial feeds for fry. Some major problems encountered in feeding artificial diets to clariids include

- The larvae do not readily accept artificial diets;

- The material used in compounding most fish feeds competes with conventional human and livestock feeds rendering the finished feed expensive.

Some substances e.g. betaine, glycine, and Spirulina have been reported to have flavour-enhancing effects when included in fish diets (Appelbaum, 1980; Henson, 1990; Hughes, 1991).

Also, Mgbenka and Orji (1994) reported that ripe, raw, fresh palm oil (FPO) used as feed attractants improved growth and acceptance of feeds to clariid larvae and fingerlings but the optimal rate is not yet known. Legendre et al. (1995) made a similar report on the growth of Heterobranchus longifilis larvae fed dietary copra and palm oils.

Food preference in larval fish has been found to depend on a host of factors (Dabrowski, 1984; Verreth and Kleyn, 1987). Ingestion of food particles offered to fish is very strongly influenced by the aroma or palatability of the food (Appelbaum, 1980; Gill, 1989), the availability of nutrients present, and the lipid level of the diet (Machiels and Van Dam, 1987; Verreth et al. 1987). There is a dearth of information on the use of local flavours such as ginger, uda, uziza, etc. as chemoattractants or chemoactivators to improve acceptance, growth, and survival.

Some non-conventional include such feed ingredients as rumen digesta, sprout (sorghum malting by-product), mucuna bean seed, and devil bean (Igbo, “agbara”), to mention a few. Mucuna bean seed and sprout, for example, have been reported to contain 28.59% and 26% crude protein, respectively (Oyenuga, 1968; Okwuosa, 1992). Additionally, the sprout is rich in the essential amino acids Lysine and Methionine (Okwuosa, 1992).

References

Amerio, M. 1983. Chemical and nutritional characteristics of earthworms; applications in

animal production. A paper presented at the International Symposium on

Agriculture and Environmental Prospects in Earthworm Farming. Rome, Italy 1-2

July 1983.

Annune, P. E. Preliminary investigation on the suitability of toad meal, (Bufo regularis

Reuss 1834) in the diets of catfish, Clarias lazera Cuvier, and Valenciennes. J.

Aquatic Sciences 5: 37 – 452.

Christensen, M. S. 1981. Preliminary test on the suitability of coffee pulp in the diets of

common carp and Clarias mossambicus. Aquaculture 25 : 235 – 245.

Ensminger, M. E. and C. G. Olentine, 1978. Feeds and Nutrition – Complete. The

Ensminger Publishing Company, Clovis California.

Coche A. G.B. Haight and M. Vincke.1994. Development and research in sub-Saharan

Africa. CIFA Technical Paper 23. 151 pp.

De Silva, S. S. and T. A. Anderson. 1995. Fish Nutrition in Aquaculture. Chapman and Hall Aquaculture Series 1. Chapman and Hall, New York. 319 pp.

FAO. 2003. State of Fisheries and Aquaculture. Food and Agricultural Organization

(FAO), Rome.

Hepher, B., J. Chervinski and H. T, Ugari. 1971. Studies on carp nutrition III.

Experiments on the effect on fish yields of dietary protein source and

concentration. Bamidgeh 23: 11 – 37.

Hepher, B. 1975. Supplementary feeding in fish culture. Proceeding International

Congress on Nutrition 9(3): 183 – 198.

Hepher, B. 1988. Principles of Fish Nutrition. Pages 121 – 142 in M. Shilo and S. Sariq

(eds). Fish Culture in Warm Water Systems: Problems and Trends. CRC Press,

New York.

Shang, Y.C. 1981. Aquaculture economics: basic concepts and methods of analysis.

Westview Press, Boulder, 145 pp.

Liener, I. E. 1980. Protease Inhibitors. Pages 7- 72 in I. E. Liener (ed.). Toxic

Constituents of Plant Feedstuffs. Academic Press, London.

Lovell, T. 1989. Nutrition and Feed in Fish. Van Nostrand Reinhold, New York, New

York.

Luquet, P. and Y. Moreau, 1990. Energy-protein management by some warm water

finfishes pages 751-756. In Advances In Tropical Aquaculture. Actes Colloq. No.

- IFREMER, Paris, France.

Mgbenka, B. O. and R. T. Lovell. 1985. Feeding combinations of extruded and pelleted

feeds to channel catfish in ponds. Prog. Fish-Cult. 48:2 38 – 241.

Mgbenka, B. O. and U. L. Agua, 1990. Digestibility of some agricultural by-products, by

African catfish (Clarias gariepinus Burchell 1822). Nig. J. Aquatic Sci. 5, 65 –

72

Mgbenka, B. O. and R. Orji, 1994. Effects of fresh palm fruit extract as a diet flavour

enhancer in the diet of larval African catfish (Clarias gariepinus Burchell, 1982).

A paper presented at the International Workshop on the Biological Bases for the

Aquaculture of the Siluriformes and Montpellier, France, May 24 – 27, 1994.

Mgbenka, B.O. and Ugwu, L.L.C. (2005). Aspects of mineral composition and growth

rate the hybrid African catfish fry fed inorganic phosphorus–supplemented diets.

Aquaculture Research, 36: 479 – 485.

New, M. B. 1987. Feed and feeding of fish and shrimp. ADCP/REP/87/26, FAO/UNDP,

Rome.

- R. C. (National Research Council). 1993, Nutrient requirements of fish. National

Academy Press, Washington, D. C.

Okwuosa, B. N. 1992. Composition and nutritive value of the by-products of

sorghum malting in broiler production. A paper presented at the 2nd National

Workshop on strategies for agriculture development and management programme

for development studies and research in Africa. The University of Agriculture,

Makurdi 8 -10 April, 1992.

Oyenuga, V. A. 1968. Nigerian food and feeding stuff. Ibadan Univeristy Press.

Pillay, T. V. R. 1980. Fish Feed Technology. Aquaculture Development and

Coordination Programme ADCP/EP/80/11. United Nations Development

programme, Food, and Agriculture Organization of the United Nations, Rome.

395 pp.

Reis, L. M., E. M. Reutebach, and R. T> Lovell, 1989. Protein-to-energy ratios in

production diets and growth, feed conversion and body composition of channel

catfish, Ictalurus punctatus. Aquaculture 77: 21 – 27.

Tacon, A. G. J., Stanfford and C. A, Edwards, 1983. A preliminary investigation of the

nutritive value of three terrestrial worms for rainbow trout. Aquaculture 35: 187 –

199.

Tacon, A. G. J 1993. Feed formulation and on-farm feed management. Pages 61 – 73 in

M . B. New and A. G. J. Tacon (eds). Farm-made Aquafeeds.

RAPA/DAO/AADCP, Bangkok, Thailand.

Ugwu, L.L.C., Mgbenka, B.O. and Asogwa, M.O. (2005). Nutrient utilization and growth responses of frys of the African hybrid catfish (Clarias gariepinus xHeterobranchus bidorsalis) to inorganic phosphorus supplements. Journal of Agriculture and Social Research, 5(1): 107 – 112.

Viola, S. U. Mokady.U.Rappaport and Y. Arieli, 1982. Partial and Complete replacement

of fish meal by soybean meal in feed for intensive culture of carp. Aquaculture,

26: 223 – 236.

Wood, J. 1993. Selecting equipment for producing farm-made aquafeeds, Pages 135 –

- In M. B. New, A. G. J. Tacon and I. Csavas (eds.) Farm-made Aquafeeds,

14 – 18.

December 1992, Bangkok, Thailand. FAO-RAPA/AADCP, Bangkok, Thailand,

434 pp.