The Art of Base Cream Formulation By Precious Okpara

Mastering the Art of Base Cream Formulation: A Step-By-Step Guide

Creating the perfect base cream formulation can be daunting. It requires a keen eye for detail and a thorough knowledge of the ingredients and techniques used. But don’t fret – mastering this art is within your grasp. This step-by-step guide will teach you the basics of formulating a base cream, from the types of ingredients to the processes and techniques used to create the perfect product. You will learn the right combination of fats, oils, and emulsifiers for your cream, as well as the steps necessary for successful homogenization and pasteurization. With this guide, you can become a base cream formulation expert and create products that are sure to please your customers.

Types of Ingredients Used in Base Cream Formulation

There are three main ingredients used in base cream formulations: fats, oils, and emulsifiers. Fats, oils, and emulsifiers are the main ingredients in all cosmetic creams and lotions, regardless of formulation type. Fats provide creaminess and emollience, while oils provide hydration, slip, and emollience. Emulsifiers are used to disperse, blend, and stabilize the fats and oils in the cream’s emulsion. The following table provides examples of the types of ingredients used in base cream formulations.

Fat and Oil Selection

The first step in formulating a base cream is to determine the right fats and oils for your product. There are many types of fats and oils available in the market and each has its own set of characteristics and benefits. It is important to choose the right ingredients that are both cost-effective and suitable for your particular formula. A few tips for selecting the right fats and oils for your formula include keeping in mind the desired texture, fragrances, and colour for your base cream. Fats and oils also perform key functions in a base cream, such as improving the creamy texture, providing emollience, and preventing water loss. Fats and oils can be categorized by their phase behaviour, which refers to how they react with other ingredients in a base cream formulation. Phase behaviour is measured by the phase diagram, which is a graph of temperature against pressure. It is important to know the phase behaviour of the fats and oils in your formula because it affects the stability of the final product. Fats and oils that are miscible with each other produce a homogeneous cream, while immiscible fats and oils produce a heterogeneous cream.

The Role of Emulsifiers

Emulsifiers are used to disperse, blend, and stabilize the fats and oils in the cream’s emulsion. They are added to the formula in the form of an emulsion, which is dispersed throughout the other ingredients. There are various types of emulsifiers available for use in a base cream formulation, but the best choice will depend on the type of cream being formulated. Each emulsifier has its own set of characteristics, such as pH and melt point. When choosing an emulsifier, it is important to consider the other ingredients in your formula. Certain emulsifiers will react differently with certain ingredients. When selecting an emulsifier for your base cream, there are a few key factors to keep in mind. The emulsifier needs to be able to withstand the desired processing conditions, such as high temperatures and shear rates. It should also be compatible with the other ingredients in your formula.

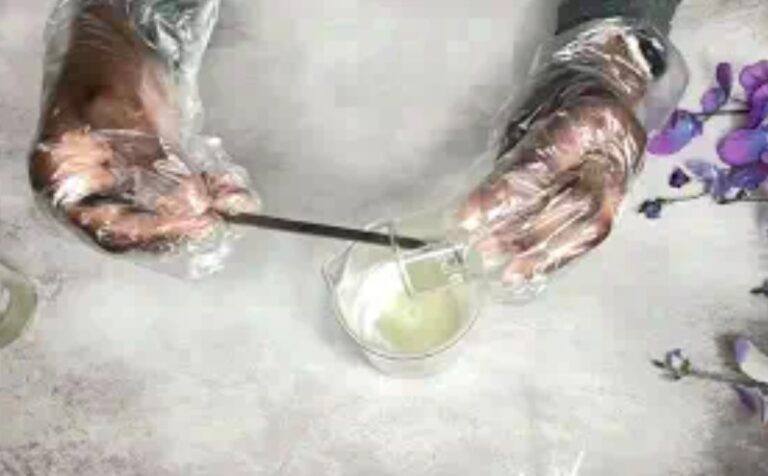

Homogenization

The cream’s emulsion is formed by dispersing the fat and oil droplets in water. The process of homogenization is used to disperse the ingredients evenly. This process can be achieved by using a homogenizer, a high-pressure pump, or a colloid mill. Homogenization of the cream’s emulsion increases the viscosity of the mixture, which prevents the formation of large fat globules. This prevents water loss from the cream and gives it its creamy texture. The homogenization process affects the stability of the final product. When homogenizing creams, it is important to ensure that the emulsion remains stable. This can be achieved by carefully controlling the homogenization process and choosing the right type of equipment.

Pasteurization

The purpose of pasteurization is to prevent contamination and extend shelf life. It is important to note that while pasteurization only kills microorganisms; it does not kill all contaminants. There are two types of pasteurization – conventional and high-temperature/short-time (HTST). Conventional pasteurization is used for products that need to remain creamy, while HTST is used for products that should remain clear. The cream’s fat and oil content will determine the process used for pasteurization. If the base cream has a low-fat content, it can be heat treated at around 84-91°C (185-197°F). A high-fat content cream, on the other hand, must be heat treated at a higher temperature, around 95-99°C (203-210°F). When selecting a pasteurization method, it is important to consider the type of process equipment available in your production facility. It is also important to know the boiling points of the ingredients in your formula, as well as their flash points.

Cooling and Packaging

Creams can be cooled and packaged in many ways, depending on the method used for pasteurization. For example, cooling to room temperature, cooling to 25°C, or cooling to 10°C, followed by aseptic packaging, is suitable for heat-treated products. Products that are not heat treated must be cooled to 5°C, followed by aseptic packaging.

Conclusion

Base cream formulation is a complex process that requires the use of many different ingredients. When formulating your base cream, it is important to select the right fats, oils, and emulsifiers for your formula. It is also important to choose the right equipment for homogenization and pasteurization. Once the base cream has been formulated, cooled, and packaged, it is ready to be shipped to customers.

You can also read DIY base cream at home.